Hippobloo

Concept

The idea of working with a raw material such as latex, which is necessary for the manufacture of our products, leads us to turn to Thailand, the world's leading exporter of natural rubber (latex, rubber, hevea milk).

The local know-how of the craftsmen is unique and recognized...

Our approach is therefore to offer a comfortable product while practicing a reasonable price policy, a "fair" price for the consumer!

To propose an alternative tp the plastic flip-flop !!!

If we join a "classic" marketing approach, the public price would be higher.

We can practice this pricing policy because our brand is known little by little, by word of mouth and we do not incur expenses in advertising campaigns, very expensive...

You find our products in committed sales points, with values...

Our distribution approach is also based on values such as respect, trust and listening to our resellers.

Hippobloo Europe is the exclusive importer of the brand throughout Europe, Hippobloo is a registered trademark.

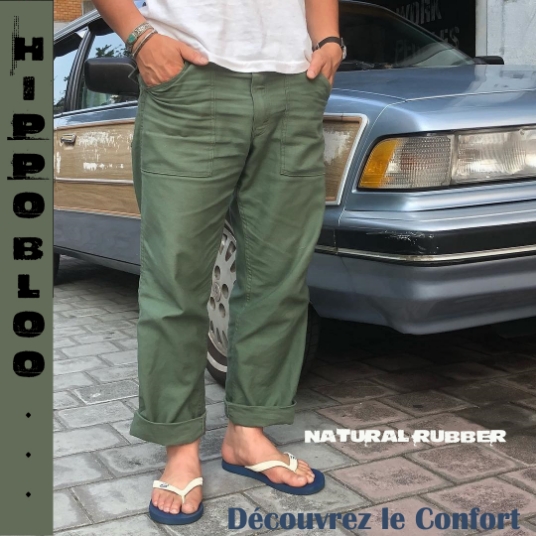

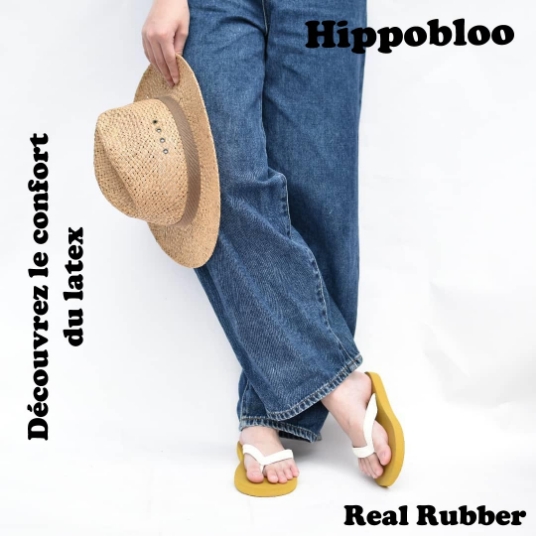

A trendy, comfortable

and robust flip flop…

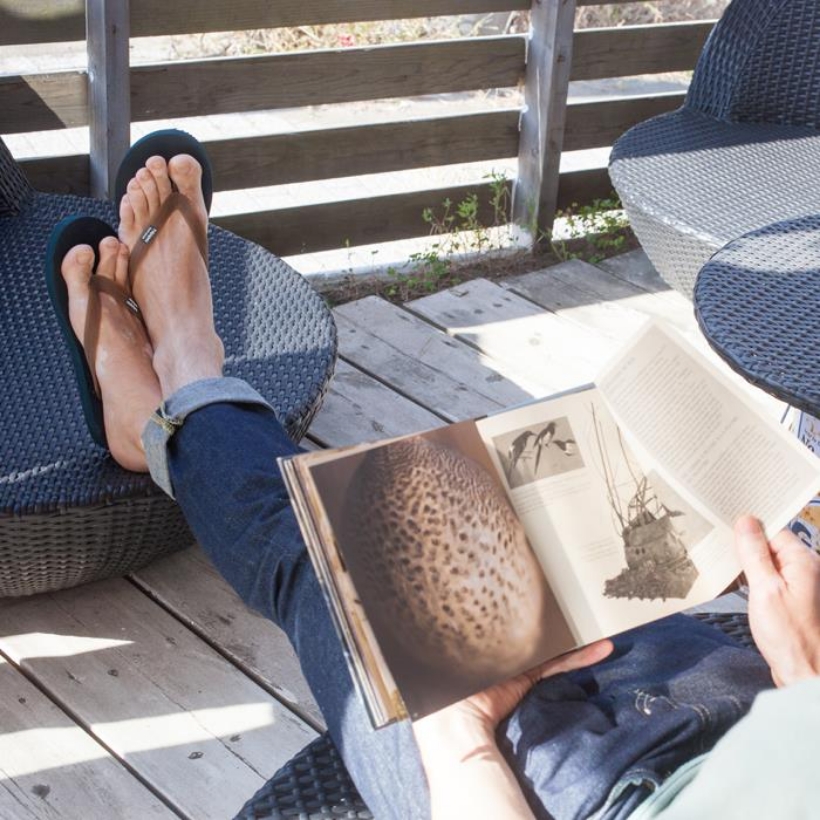

At the same time a basic and a must of the summer, the Hippobloo flip flops are distinguished by their comfort, their style and their their lifespan.

We made the choice to use latex so that our flip-flop is supple, comfortable and resistant at the same time.

The slogan "great comfort for the foot and one step for the planet", reflects the philosophy of the brand.

Aware that people must always be the center of attention, Hippobloo has set up a chain of production of latex flip flops, rubber sap.

To produce Hippobloo flip flops for men, women and children, Hippobloo gets its supplies from two producers of rubber, we pay a fee for 0.5 € / kg of rubber.

This supply chain was brought to us by the Fair Rubber association of which we are today member.

Hippobloo flip flops are very COMFORTABLE.

The number of stores offering Hippobloo thongs is constantly growing, a sign of a quality of ethics and very interesting comfort.

The consumer is the first judge !

Comparing our product with other brands you will find good quality for a price often very lower...

To try it is to adopt it...

We have the Thai know-how from the artisans we work with !

Millions of flip flops are made in Thailand, of various qualities, we opted for a product of good manufacture.

The know-how of our Thai artisans, from the rubber harvest to its manufacturing and processing, allows us to offer you a good quality product.

Moreover, we wish by our approach to bring to all the craftsmen, the employees, a stable and sustainable through our longevity and the growth of our Hippobloo brand.

Increasingly general awareness makes us say that we are actors and that we must react and change our mode of consumption.

To complete our approach, the routing of our product, is by boat, once a year.

We are also a member of 1% For the Planet.

we decided to donate 1% of our turnover to associations saving the planet.

These associations are referenced by the 1% for the Planet network.

Découvrir 1% Pour la Planète

Latex from the rubber tree

Thailand is one of the main producers of natural rubber, vegetable latex, pure juice from the rubber tree.

Latex is harvested by tapping the bark of the rubber tree trunk (called Ton Yang in Thai).

Using a very specific tool (called Mid in Thai) and a very specific hand, the know-how of the craftsmen begins here so as not to damage the throat or the latex will flow.

A small tongue (called Line Yang in Thai) and added to the trunk of the tree so that the latex flows well into its ceramic container (called touayang in Thai).

Farmers make a small cut in part of the rubber tree, then gradually bleed the tree as they work their way down.

The bleeding generally begins at the height of a man, then gradually descends.

At each bleeding, the notch is revived by cutting a thin strip of barely about 2 mm thick.

This is the gesture that must be very precise so as not to remove too much thickness from the latex flow groove.

However, it is important not to touch the wood generator as this causes scarring and reduced yield.

Asia is the main producing region of natural rubber (95% of the world total).

The top three natural rubber producing countries in order are Thailand, Malaysia and Vietnam.

Français

Français

English

English